Note: This article only contains rough guidelines. Some manufacturers have built presses that require more or less tie rod pre-stress. Your owner’s manual and the original manufacturer should be consulted whenever possible prior to any work commencing. The press builder should always be the primary source of tie rod pre-stress information. You should seek a press expert’s opinion if no manual is available to you.

To pre-stress the frame, tie rods are “shrunk”. There are four methods for shrinking tie rods:

- Torch heating

- Cal-rod heating

- Hydraulic nuts

- Tensioning nuts

No matter what method is used the amount of shrinking is the same. The following chart shows the amount of shrink required.

| Tie Rod Diameter | Up to 3 ¼” | 3 ½-4” | 4 ¼-7” | 7” & over |

|---|---|---|---|---|

| Shrinkage/inch* | 0.0006” | 0.00063” | 0.00066” | 0.0007” |

| (*total distance between nuts) |

Care must be taken not to exceed the required amount of shrinking. Over shrinking rods can distort the frame and cause considerable damage to the press. Regardless of the method used, all four rods should be reshrunk at the same time. If an accident has stretched just one tie rod, all four rods must be loosened and reshrunk.

Used Tie Rods: Tie rods can become damaged by overheating or by being stretched too many times. Before shrinking a used set of tie rods, they should be inspected for lengthwise cracks in the heat-affected areas. They should also be checked for a reduction in diameter, typically in heat affected areas. If a reduction in diameter exceeding 1/8” is found, the tie rod should be replaced.

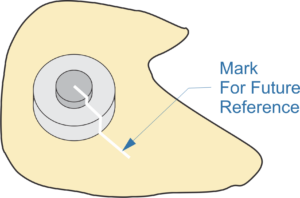

Procedure: When shrinking tie rods, clean and deburr the frame and nut surfaces that will be involved. Drive the nuts up tight and mark the rods, nuts, and frame, top and bottom so it can be determined if something moves that is not supposed to.

When using heat, torch or calrod, it is preferred to tighten the lower nuts. If the lower nuts are inaccessible, the top nuts may be tightened, however, the tie rods must be blocked up to keep the lower nut against the frame. If torch heating, loosen the nut ½ turn, and check the marks to be certain the opposite end has not moved. Apply heat until the rod has expanded sufficiently to insert a gage that is the thickness of the required shrinkage. Tighten nuts and allow rods to cool completely before using the press. It is best to shrink all four rods at the same time, if this is not possible, they should be shrunk in pairs of opposite rods, cross corner.

Calrod Specifics: Calrod heating, while much easier than torch heating, does present a few problems. The calrod must fit the hole in the tie rod. If the calrod extends out of the tie rod, the calrod can “burst”. Also if the hole in the tie rod is more than .012” larger than the cold calrod, the calrod may “burst” or not transfer enough heat to stretch the tie rod. A light gauge shim the full depth of the tie rod hole may be used to accomplish the proper clearance. Another problem encountered with calrods. When the top nut must be tightened, the heat from the calrod may expand the tie rod diameter making it impossible to turn the nut. In this cause it is necessary to heat the tie rod nuts with a torch so they can be turned.

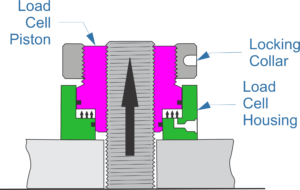

Hydraulic Nut Specifics: Most modern presses are fitted with hydraulic nuts to shrink the tie rods. It is still important that the surfaces involved are Hydraulic Nut Cross Section clean and deburred. The nuts are driven up tight and then pumped up with a hydraulic pump. Shims of the proper thickness are inserted and the hydraulic pressure is released. Hydraulic nuts are available in the aftermarket. Unfortunately, many presses do not have the space required for installation because hydraulic nuts are normally larger in diameter and require a slightly longer tie rod. There are aftermarket hydraulic nuts that are the same basic sizes as standard tie rod nuts, however they are very expensive and require special high-pressure pumps.

Tensioning Nuts Specifics: Superbolt MJTTensioning nuts are also available for shrinking tie rods. These are nuts that are the same basic size as typical tie rod nuts and have a ring of jackbolts that are used to tension the tie rods. They are installed in place of the existing tie rod nuts. The jackbolts are tightened with a torque wrench until the required pretension is achieved.

How do you know if a tie rod is loose?

- If the crown is lifting off the column, even if it is just one corner, the tie rod is stretched

- Cracked paint between the column and crown is often a sign that the tie rod is stretched

- Oil seeping from between the crown and column is also a sign of a loose tie rod

- Some tonnage monitor readings can indicate a loose tie rod

How long can the press run with a loose tie rod?

If a press is run with a loose tie rod it will not develop the proper tonnage. Proper alignment of the frame is lost which can severely damage the press and the dies. Running a press with a loose tie rod, for any amount of time can lead to very expensive repairs.

Do I have to exceed the press tonnage to stretch a tie rod?

No – Keep in mind that each individual tie rod is preloaded to 50% the press tonnage, an offset load that does not exceed the rated tonnage of the press can still stretch a tie rod.

Author: Dave Cooper III CHP Systems, Inc.

Edited By: Mike Gruber, BSME Variegate, Inc.

Copyright Notice:

The materials and services on this site are protected by copyright and/or other intellectual property laws and any unauthorized use of the materials or services at this site may violate such laws. Except as expressly provided herein, Variegate, Inc., CHP Systems and its suppliers do not grant any express or implied right to you under any patents, copyrights, trademarks, or trade secret information with respect to the materials and services.

Except as specifically permitted herein, no portion of the information or documents on this site may be reproduced in any form or by any means without the prior written permission of Variegate, Inc. or CHP Systems.